Thermal

conductivity

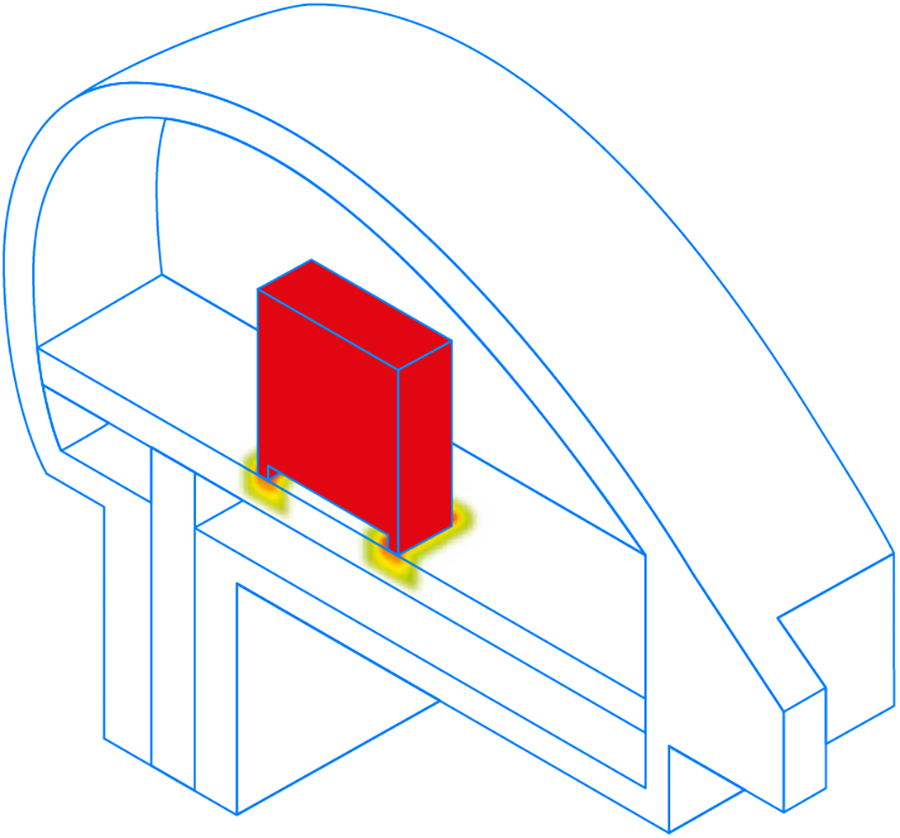

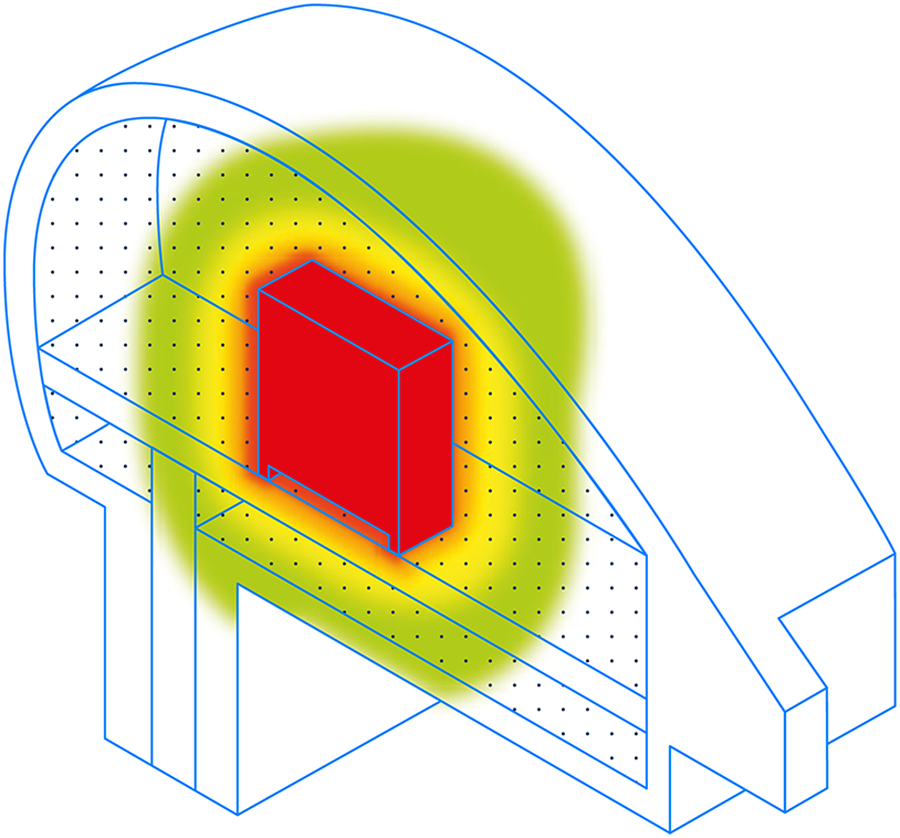

Encapsulating materials with high thermal conductivity can reliably absorb and dissipate the heat generated by e.g. circuit boards, ICs and motors during operation. Improved control and reduction of hot spots prolong component life and allow even smaller components to be designed.

Representative products

WEVOPOX 2513 / WEVODUR 1003/07

- Thermal conductivity 1.4 W/m·K

- Insulation class H (180 °C)

- Thermosetting

- Good impregnation characteristics

WEVOSIL 26005 FL

- High thermal conductivity

- Very elastic with damping properties

- High thermal stability (200 °C)

- Conventional thermal conductivity mats

- Flame-retardant properties in accordance with UL 94 V-0