In PEM (proton exchange membrane) fuel cells, humidifying the incoming air is crucial for maintaining the conductivity of the membrane – and thus the efficiency of the entire system. This task is mainly performed by flat-sheet membrane and hollow fibre membrane humidifiers.

Flat-sheet membrane humidifiers: precise bonding and gas-tight sealing

Flat-sheet membrane humidifiers often consist of several hundred layers of membrane and spacer materials, which must be reliably and permanently bonded together to form a stack. In many cases, this stack is additionally glued into the housing of the humidifier or partially encapsulated to achieve a gas-tight seal.

Wevo has developed hydrophobic adhesives and potting compounds to meet these requirements. Their water-repellent polymer backbone also makes them suitable for use as hydrolysis- and temperature-resistant sealants. The 2-component (2K) polyurethanes and silicones adhere very effectively to the substrates most commonly used as spacers, including polyolefins, polyphenylene sulphide (PPS) and fluorinated membrane materials – the bonding of which has been a challenge up to now.

Another characteristic of special Wevo formulations is their low glass transition temperature, which ensures high tear resistance, long-lasting elasticity and resistance to temperature changes – essential when cold-starting fuel cell systems.

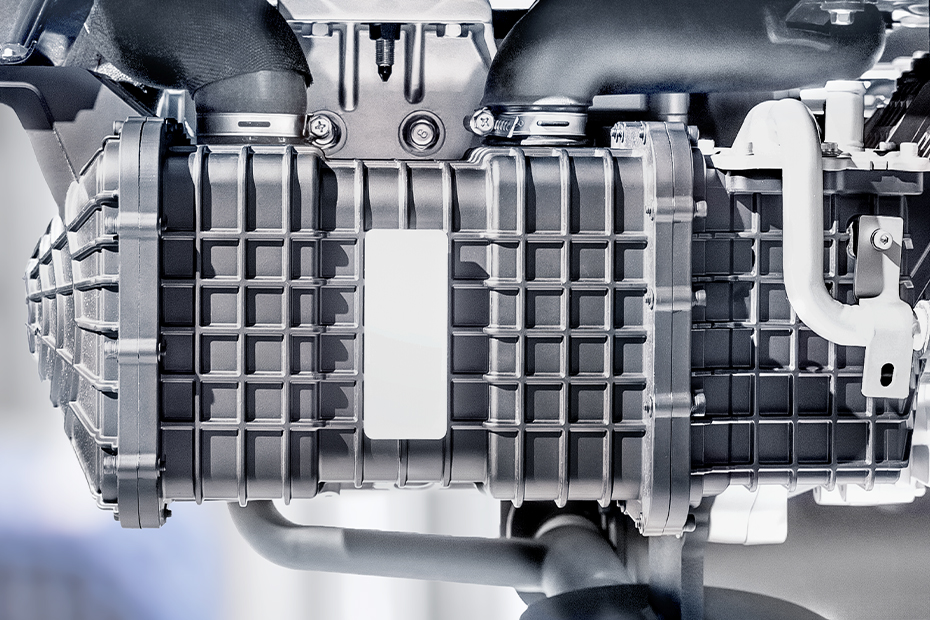

Hollow fibre membrane humidifiers: controlled reaction heat and excellent wetting

In hollow fibre membrane humidifiers, bundles of tubular membranes are potted into a support tube at both ends – a principle familiar from water filtration. The resins must penetrate between the hollow fibres and ensure sufficient wetting of the bundle without clogging the individual fibres.

For this reason, Wevo’s potting compounds have been designed for optimal exothermicity. The heat generated during the reaction between the resin and hardener is therefore controlled, effectively preventing oxidative damage to the sensitive membrane tubes. At the same time, the 2K polyurethane systems are hydrophobic to prevent a reaction with the moisture contained in the membrane material and consequently bubble-formation.

Efficient production of humidifier modules

All Wevo materials can be applied by standard mixing and dosing systems and thus integrated into both semi- and fully automated production lines. Processing properties such as viscosity and pot life can be customised to meet individual requirements on request. Curing usually takes place at room temperature. However, to accelerate manufacturing cycles, it is also possible to use thermal curing in a convection oven or via infrared radiators.

Bonding and sealing further humidifier components

Wevo’s 2K systems can also be used for other applications in humidifiers, such as for sealing and bonding housings, for seals on water inlets and outlets, for sealing and bonding bypass valves, and for creating internally sealed zones.

Solutions for innovations in fuel cell technology

Wevo develops special formulations for fuel cells, electrolysers and BOP components in close collaboration with manufacturers and research institutes. If required, materials based on polyurethane, epoxy resin and silicone can be adapted to suit individual needs by incorporating numerous further properties – in addition to the parameters relevant for processing. Among other things, viscosity, gas permeability (e.g. hydrogen and water vapour permeability) and adhesive properties can be precisely adjusted.

Wevo is thus making a vital contribution to the technological advancement of hydrogen technologies – whether through highly resistant hydrogen seals or low-VOC adhesives for PEM fuel cells.