Silicones for

electronics and

electrical engineering

Customised potting compounds, gels, adhesives and sealants

Wevo silicones afford optimum protection for electronic components in demanding applications. Our WEVOSIL products provide excellent elasticity, efficient heat dissipation, low gas diffusion, high chemical resistance and temperature stability plus electrical insulation – from 2K potting compounds, adhesives and sealants to silicone gels and coatings. Each one can be tailored to your individual requirements. Find out more – or get in touch with us today.

Silicone potting compounds | Silicone adhesives | Silicone sealants | Gap fillers | Silicone gels | Silicone coatings | Liquid silicone rubber (LSR)

The Wevo silicones portfolio – customised products for a wide range of applications

As a Germany-based silicones manufacturer with many years of expertise, we offer innovative materials designed for maximum durability and performance – even under extreme mechanical, thermal or weather conditions. Our RTV-2 (room-temperature-vulcanising) silicones ship with a whole series of customisable properties. Whether you choose a standard formulation or a specially developed material, with silicone systems from Wevo you benefit from solutions that set new benchmarks in terms of quality and reliability.

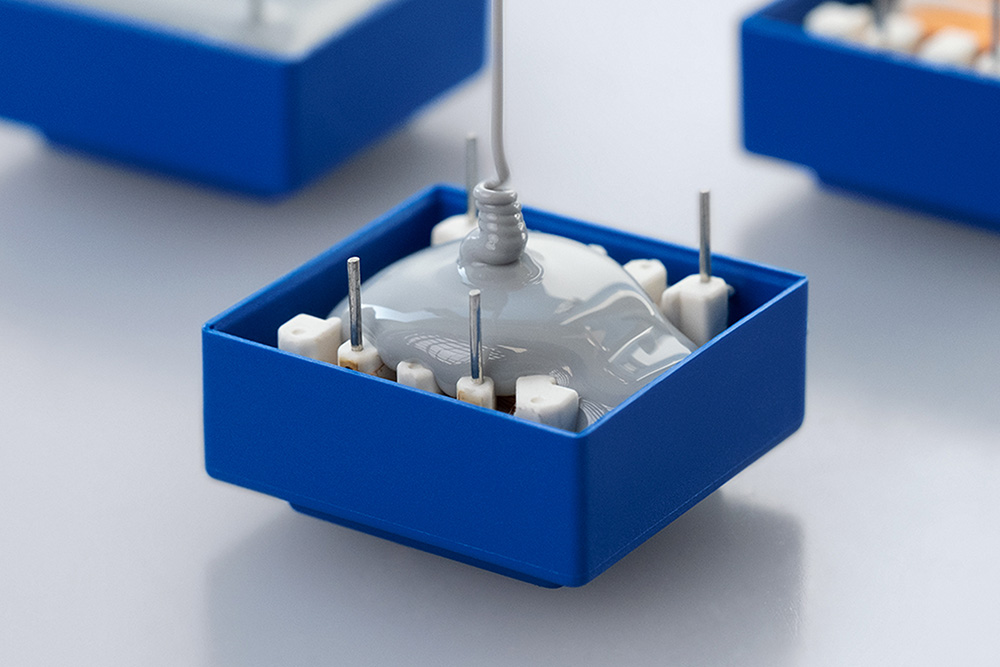

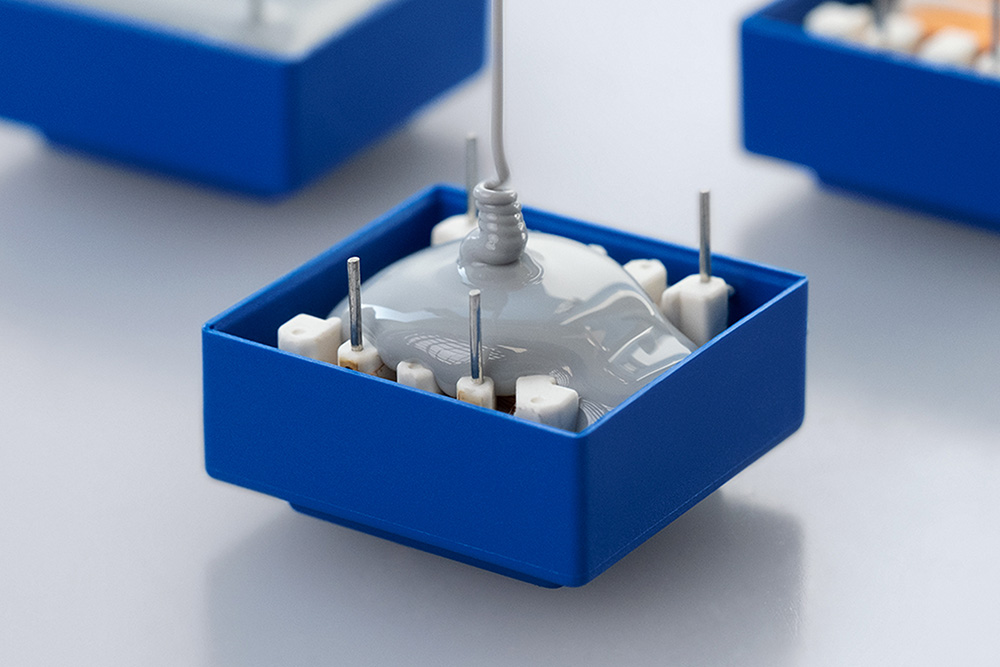

Silicone potting compounds – protection and heat dissipation for sensitive electronics

2K silicone potting compounds provide adaptable protection – against external influences such as dust, moisture and aggressive media or against mechanical stresses. Thanks to a combination of high thermal conductivity and optimum flowability, our silicone-based potting resins ensure efficient thermal management and allow complex component geometries to be filled without air pockets. They can also be customised, for example for improved flame-retardant properties, electrical conductivity or insulation. If optical applications are the goal, Wevo creates clear, transparent systems characterised by high UV resistance and zero yellowing.

Silicone potting compounds – protection and heat dissipation for sensitive electronics

2K silicone potting compounds provide adaptable protection – against external influences such as dust, moisture and aggressive media or against mechanical stresses. Thanks to a combination of high thermal conductivity and optimum flowability, our silicone-based potting resins ensure efficient thermal management and allow complex component geometries to be filled without air pockets. They can also be customised, for example for improved flame-retardant properties, electrical conductivity or insulation. If optical applications are the goal, Wevo creates clear, transparent systems characterised by high UV resistance and zero yellowing.

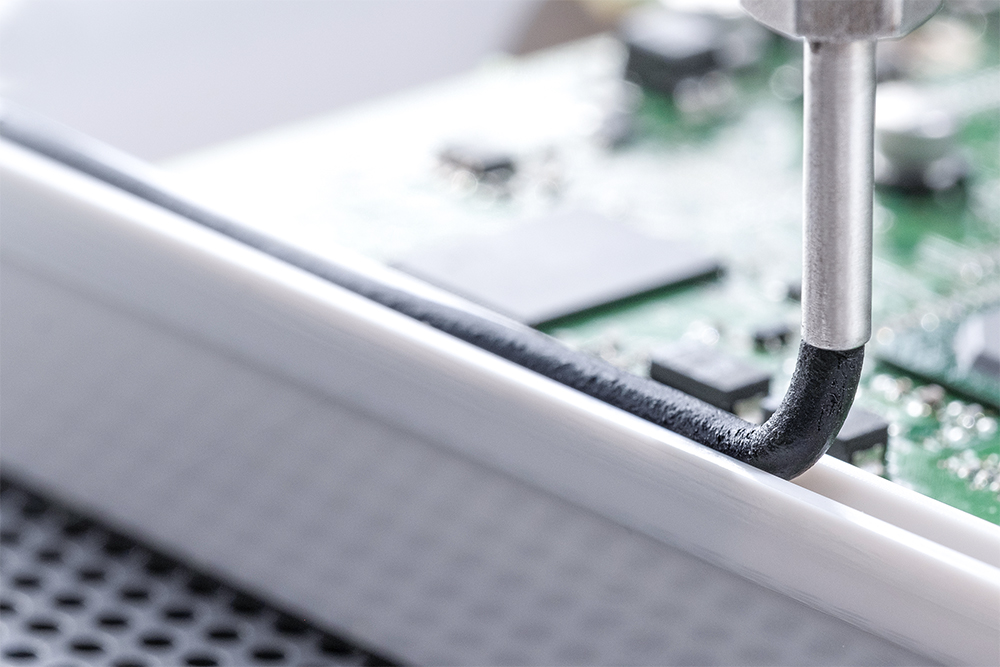

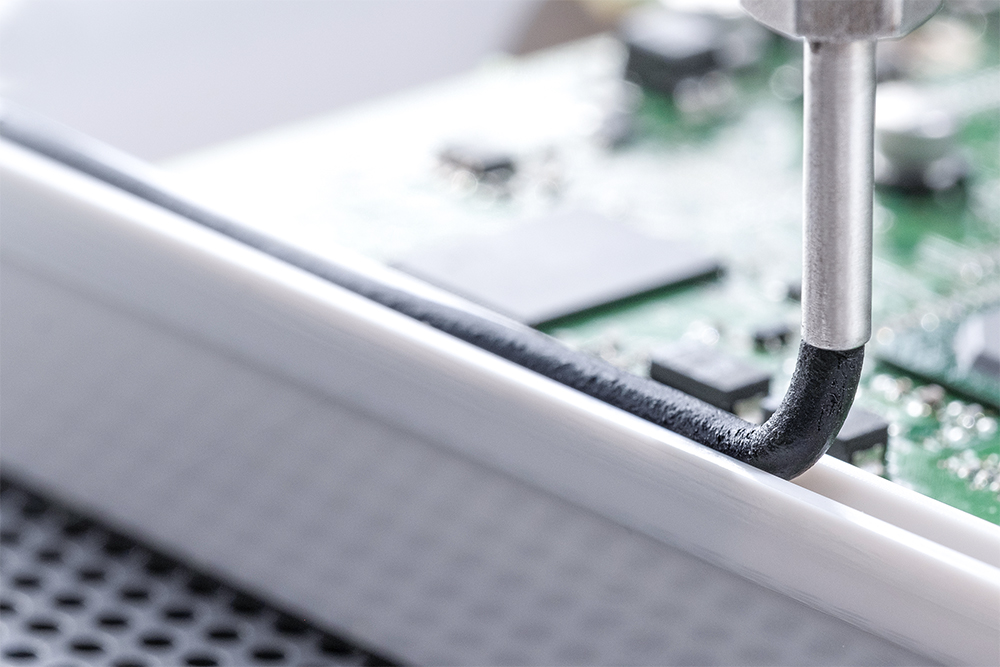

Silicone adhesives – excellent adhesion for demanding applications

Very good thermal and chemical resistance combined with outstanding flexibility – these are key characteristics of any silicone adhesive for demanding applications in the electrical and automotive industries or in power engineering. A durable and reliable bond is likewise guaranteed, no matter how challenging the conditions: our industrial adhesives offer a wide range of properties that can be tailored to meet specific requirements – for example, adhesion, thermal conductivity, electrical insulation resistance, and flow behaviour or stability.

Silicone adhesives – excellent adhesion for demanding applications

Very good thermal and chemical resistance combined with outstanding flexibility – these are key characteristics of any silicone adhesive for demanding applications in the electrical and automotive industries or in power engineering. A durable and reliable bond is likewise guaranteed, no matter how challenging the conditions: our industrial adhesives offer a wide range of properties that can be tailored to meet specific requirements – for example, adhesion, thermal conductivity, electrical insulation resistance, and flow behaviour or stability.

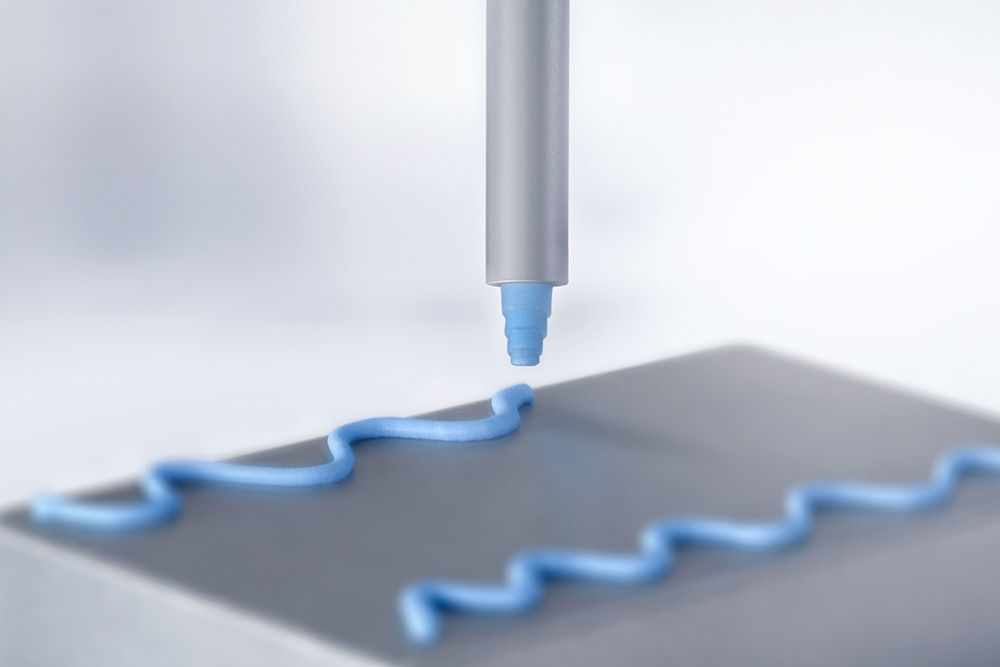

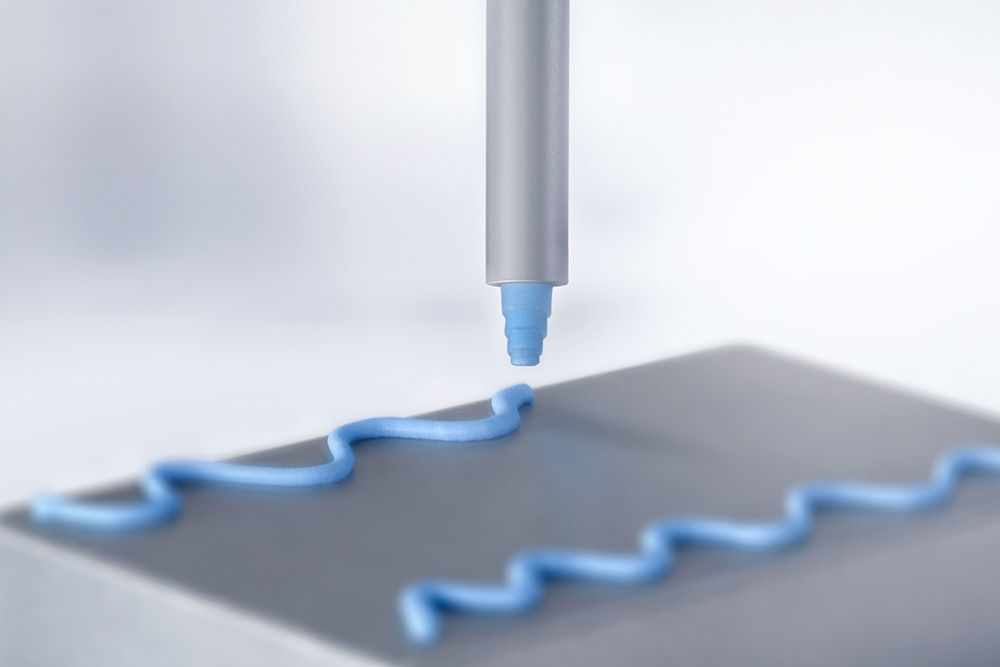

Silicone sealants – reliable protection under extreme conditions

Silicone sealants are paste-like or liquid materials that form a permanent seal against liquids, gases or other environmental influences when cured. Wevo’s specially developed liquid sealants impress with outstanding chemical resistance to acids, alkalis and aggressive media such as fuel cell electrolytes. And that’s not all: they are just as good at withstanding mechanical stresses, high temperatures or extreme ambient conditions. On request, Wevo can adapt a material’s thixotropy to customer-specific requirements to enable efficient application as cured-in-place gaskets (CIPG) or formed-in-place gaskets (FIPG).

Silicone sealants – reliable protection under extreme conditions

Silicone sealants are paste-like or liquid materials that form a permanent seal against liquids, gases or other environmental influences when cured. Wevo’s specially developed liquid sealants impress with outstanding chemical resistance to acids, alkalis and aggressive media such as fuel cell electrolytes. And that’s not all: they are just as good at withstanding mechanical stresses, high temperatures or extreme ambient conditions. On request, Wevo can adapt a material’s thixotropy to customer-specific requirements to enable efficient application as cured-in-place gaskets (CIPG) or formed-in-place gaskets (FIPG).

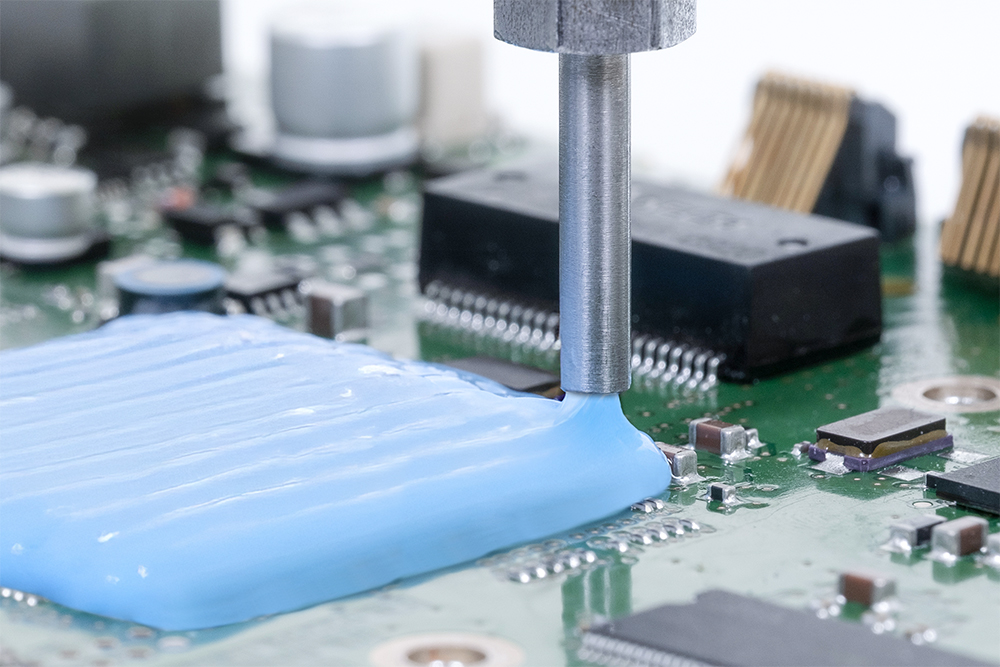

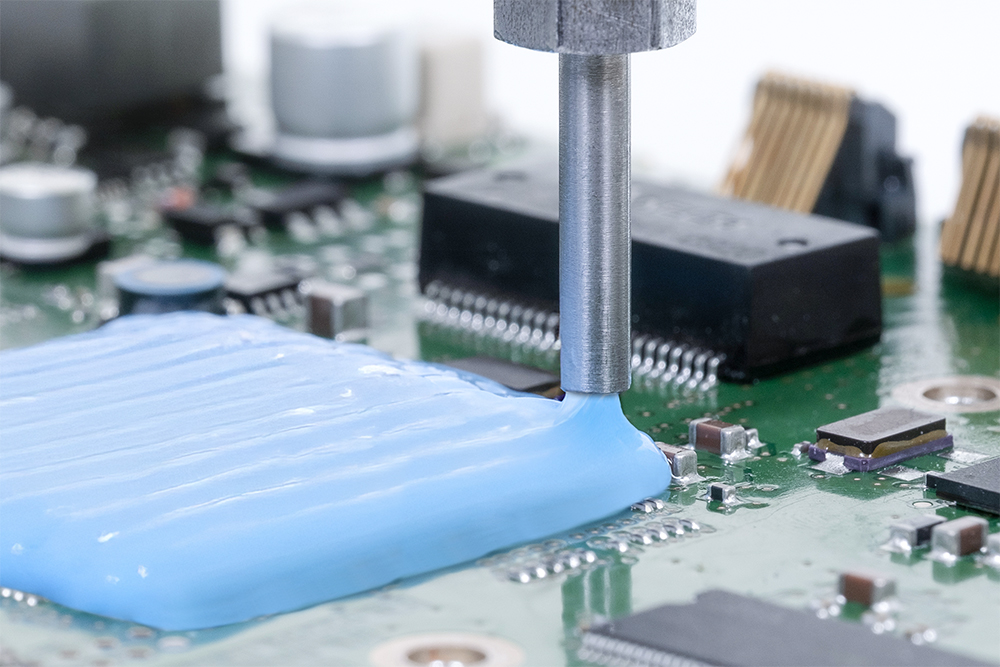

Gap fillers – thermally conductive materials for efficient thermal management

Our silicone gap fillers compensate for manufacturing tolerances and reduce thermal resistance, making them indispensable in many cutting-edge technologies featuring sensitive electronic components. WEVOSIL products offer high thermal conductivity of up to 4.0 W/m·K for this purpose. The adjustable thixotropy (from very flowable to paste-like) means the materials are extremely easy to process. As such, they are adaptable to any component geometry. Depending on the requirements, flame-retardant properties in accordance with UL 94 are possible along with high temperature stability up to 200 °C. Further information on our silicone gap filler WEVOSIL 26040 FL.

Gap fillers – thermally conductive materials for efficient thermal management

Our silicone gap fillers compensate for manufacturing tolerances and reduce thermal resistance, making them indispensable in many cutting-edge technologies featuring sensitive electronic components. WEVOSIL products offer high thermal conductivity of up to 4.0 W/m·K for this purpose. The adjustable thixotropy (from very flowable to paste-like) means the materials are extremely easy to process. As such, they are adaptable to any component geometry. Depending on the requirements, flame-retardant properties in accordance with UL 94 are possible along with high temperature stability up to 200 °C. Further information on our silicone gap filler WEVOSIL 26040 FL.

With WEVOSIL, you benefit from long-lasting protection, high elasticity and optimum thermal management – plus easy processing.

With WEVOSIL, you benefit from long-lasting protection, high elasticity and optimum thermal management – plus easy processing.

Silicone gels – flexible protection for electronic components

Silicone gel is a viscoelastic material that cures to form a flexible, elastomeric state. The 2K silicone gels developed by Wevo for electronics and electrical engineering offer up to 50 per cent lower viscosity compared to standard products available in the market. This excellent flowability ensures complete filling and efficient electronics potting, no matter how complex the assembly. Another advantage: Many material properties can be customised – for example, penetration, processing time and colour. Find out more about our silicone gels.

Silicone gels – flexible protection for electronic components

Silicone gel is a viscoelastic material that cures to form a flexible, elastomeric state. The 2K silicone gels developed by Wevo for electronics and electrical engineering offer up to 50 per cent lower viscosity compared to standard products available in the market. This excellent flowability ensures complete filling and efficient electronics potting, no matter how complex the assembly. Another advantage: Many material properties can be customised – for example, penetration, processing time and colour. Find out more about our silicone gels.

Silicone coatings – protection for sensitive PCBs and components

Silicone coatings comprise a thin layer of high-performance silicone polymers that are applied directly to the electronic component or printed circuit board. Our tailor-made materials provide targeted protection against moisture, chemicals or the weather. They also offer numerous customisable properties including flame retardancy and outstanding electrical insulation. Thanks to their high temperature resistance, they are ideal for demanding applications. Variants with electrically conductive silicone are additionally available on request to meet specific requirements.

Silicone coatings – protection for sensitive PCBs and components

Silicone coatings comprise a thin layer of high-performance silicone polymers that are applied directly to the electronic component or printed circuit board. Our tailor-made materials provide targeted protection against moisture, chemicals or the weather. They also offer numerous customisable properties including flame retardancy and outstanding electrical insulation. Thanks to their high temperature resistance, they are ideal for demanding applications. Variants with electrically conductive silicone are additionally available on request to meet specific requirements.

Liquid silicone rubber (LSR) – high-precision solutions for technical applications

Our LSRs, which are suitable for screen printing, impress with very reliable sealing, high resistance and outstanding mechanical properties. Self-adhesive product variants can be supplied too for particularly efficient processing. Bipolar plates in fuel cells or electrolysers and technical textile coatings – for instance for structure reinforcements, anti-slip surfaces or flexible electrical circuits – are just a few of the potential uses. Liquid silicone rubbers from Wevo enable durable and precise solutions in highly specialised applications.

Liquid silicone rubber (LSR) – high-precision solutions for technical applications

Our LSRs, which are suitable for screen printing, impress with very reliable sealing, high resistance and outstanding mechanical properties. Self-adhesive product variants can be supplied too for particularly efficient processing. Bipolar plates in fuel cells or electrolysers and technical textile coatings – for instance for structure reinforcements, anti-slip surfaces or flexible electrical circuits – are just a few of the potential uses. Liquid silicone rubbers from Wevo enable durable and precise solutions in highly specialised applications.

Convinced? Get in touch with us today!

Wevo-Chemie is your partner for silicone electro casting resins combining precision, performance and durability. We look forward to finding the right solution for your application, too. Let our experts advise you!

Contact us at +49 711 167 61-0 or by Email.

Convinced? Get in touch with us today!

Wevo-Chemie is your partner for silicone electro casting resins combining precision, performance and durability. We look forward to finding the right solution for your application, too. Let our experts advise you!

Contact us at +49 711 167 61-0 or by Email.

Typical applications for our silicone materials

Wevo silicones contribute significantly to advances in cutting-edge technologies – from batteries and power electronics to optical applications.

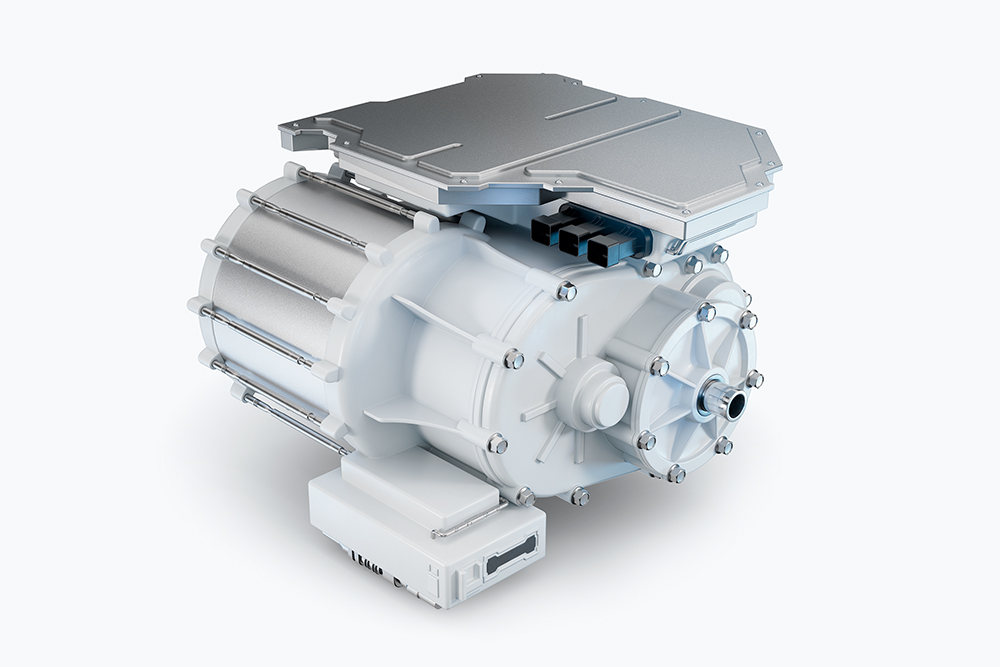

Highly thermally conductive potting compounds for electric motors

The high power density of modern stators and winding heads means thermally conductive materials have to be specially developed. These customised Wevo products adhere permanently to the stator housing, paving the way for efficient thermal management. Electrical insulation, corrosion protection and protection against vibration are other benefits attributable to our silicones.

Find out more

Highly thermally conductive potting compounds for electric motors

The high power density of modern stators and winding heads means thermally conductive materials have to be specially developed. These customised Wevo products adhere permanently to the stator housing, paving the way for efficient thermal management. Electrical insulation, corrosion protection and protection against vibration are other benefits attributable to our silicones.

Find out more

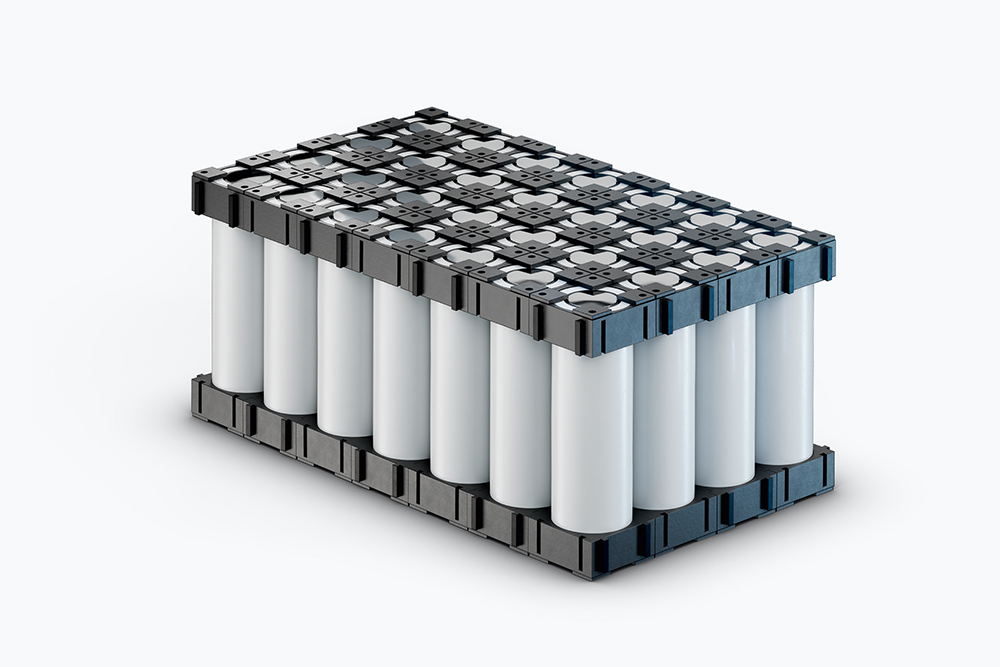

Safe, high-performance lithium-ion batteries with Wevo silicones

To specifically prevent thermal runaway, Wevo silicones serve as efficient thermal, mechanical and electrical barriers for battery modules and packs. In addition to very high heat and flame resistance, they also permit a reduction in overall weight compared to mineral or metal filled compounds.

Find out more

Safe, high-performance lithium-ion batteries with Wevo silicones

To specifically prevent thermal runaway, Wevo silicones serve as efficient thermal, mechanical and electrical barriers for battery modules and packs. In addition to very high heat and flame resistance, they also permit a reduction in overall weight compared to mineral or metal filled compounds.

Find out more

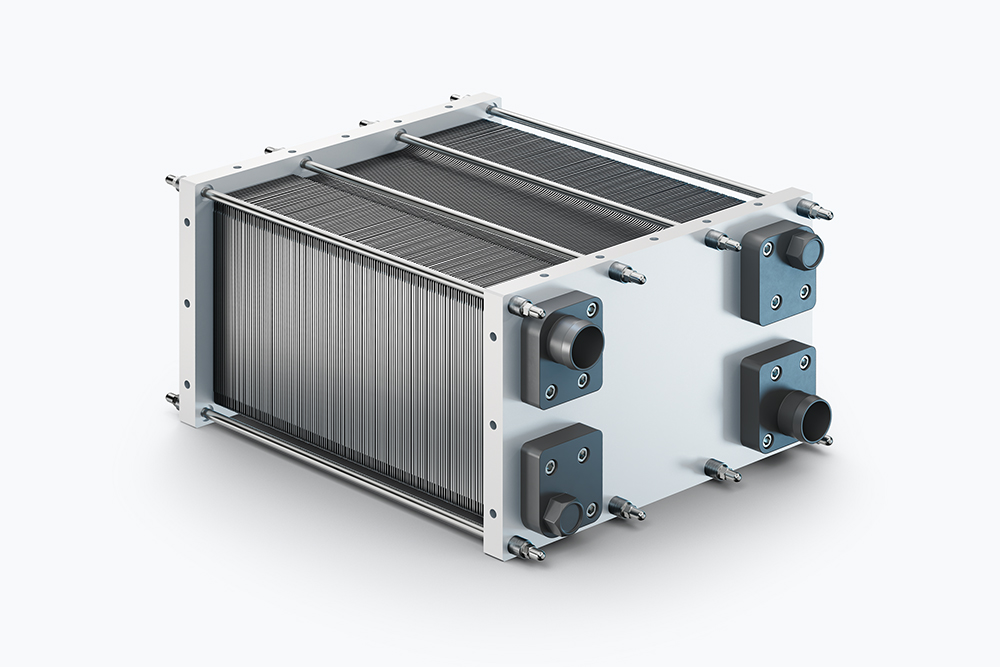

Adhesives and sealants for fuel cells and electrolysers

As the smallest of all atoms, hydrogen calls for materials that create a particularly tight seal. The silicone adhesives and sealants specially developed by Wevo for this purpose meet these high requirements – while helping to automate the production process.

Find out more

Adhesives and sealants for fuel cells and electrolysers

As the smallest of all atoms, hydrogen calls for materials that create a particularly tight seal. The silicone adhesives and sealants specially developed by Wevo for this purpose meet these high requirements – while helping to automate the production process.

Find out more

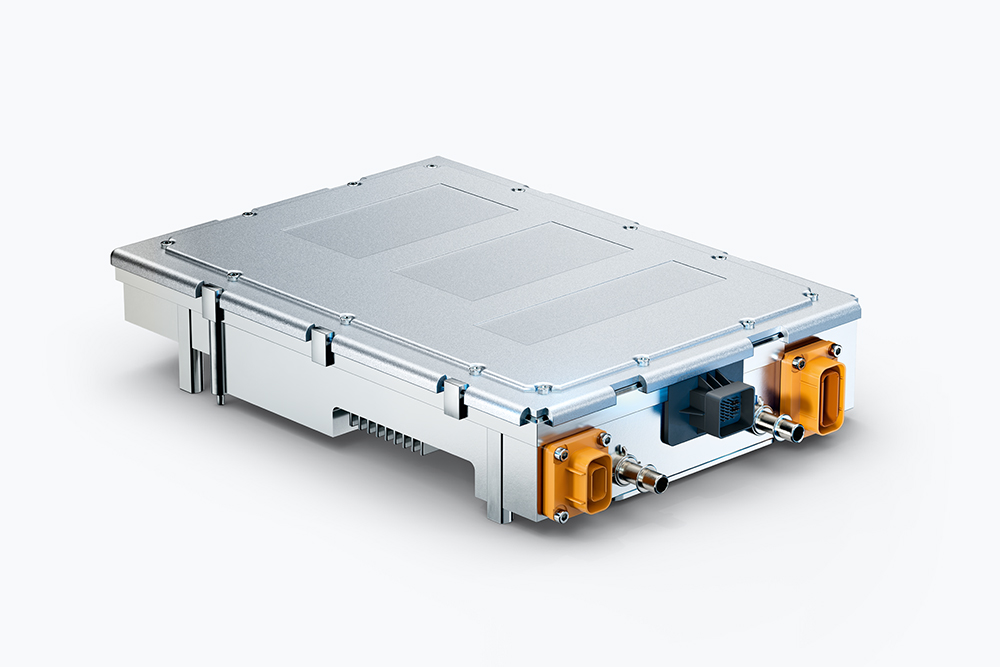

Silicones for modern power electronics

Amongst other things, thermally conductive silicone potting compounds, gap fillers and silicone gels from Wevo enable essential thermal management for on-board chargers and DC/DC converters. Fast cycle times that facilitate efficient serial production can likewise be achieved thanks to customisable parameters such as flow behaviour or pot life.

Find out more

Silicones for modern power electronics

Amongst other things, thermally conductive silicone potting compounds, gap fillers and silicone gels from Wevo enable essential thermal management for on-board chargers and DC/DC converters. Fast cycle times that facilitate efficient serial production can likewise be achieved thanks to customisable parameters such as flow behaviour or pot life.

Find out more

Why silicone? Features and advantages for your technology

Silicone consists of siloxane and is, by definition, a synthetic polymer. The high bonding energy between the silicon and oxygen atoms of the siloxanes is responsible for the high temperature and UV resistance of our silicone potting materials.

Main features of our silicone products:

- Outstanding temperature resistance: up to +180 °C; special formulations from 250 to 300 °C

- High chemical resistance: for example, to aggressive media

- Excellent thermal conductivity: up to 4.0 W/m·K

- Reliable electrical insulation: safety for sensitive components

- Very good mechanical properties: high flexibility and robustness

- Easy processing: 1:1 mixing ratio for efficient handling

- Little or no labelling in most cases: compliant with all current industry standards

WEVOSIL products combine all the advantages of addition-curing RTV-2 silicone systems. Since they cure without by-products, high dimensional stability is assured.

Why silicone? Features and advantages for your technology

Silicone consists of siloxane and is, by definition, a synthetic polymer. The high bonding energy between the silicon and oxygen atoms of the siloxanes is responsible for the high temperature and UV resistance of our silicone potting materials. Main features of our silicone products:

Outstanding temperature resistance: up to +180 °C; special formulations from 250 to 300 °C

High chemical resistance: for example, to aggressive media

Excellent thermal conductivity: up to 4.0 W/m·K

Reliable electrical insulation: safety for sensitive components

Very good mechanical properties: high flexibility and robustness

Easy processing: 1:1 mixing ratio for efficient handling

Little or no labelling in most cases: compliant with all current industry standards

WEVOSIL products combine all the advantages of addition-curing RTV-2 silicone systems. Since they cure without by-products, high dimensional stability is assured.

Examples of silicone products

Wevo stands for innovative silicone solutions to meet the highest technical requirements. With 80 years of experience in product development and application technology, we offer customised formulations for a wide range of industries. In-house production at our company headquarters in Ostfildern, south-west Germany, lays the foundation for the high quality of our liquid silicones. Here you will find some product examples and technical data.

| Product category | Silicone potting compound | Silicone adhesive | Silicone sealant | Silicone gap filler | Silicone gel | Silicone coating | LSR |

| WEVOSIL A/B | 22066 FL | 28001 | 28102 | 26040 FL | 20201 | 22027 FL | 23010 |

| Operating temperature [°C] | –60 bis +180 | –60 bis +200 | –60 bis +200 | –60 bis +200 | –60 bis +180 | –60 bis +180 | –60 bis +200 |

| Flammability UL 94 | V-0 | V-1 | – | V-0 | – | V-1 | – |

| Shore hardness 00/A | -- / 35–45 | -- / 60–70 | -- / 35–45 | 60–80 / -- | gel | -- / 25–35 | -- / 10–15 |

| Thermal conductivity [W/m·K] | 0.80 | 0.35 | 0.30 | 4.00 | 0.25 | 0.30 | 0.25 |

| Mixed viscosity [mPa·s] | 1,500– 2,500 | 30,000– 60,000 | 250,000– 350,000 | 100,000– 150,000 | 300– 700 | 700– 1,300 | 70,000– 110,000 |

| Feature | General purpose | Selfleveling adhesive | Thixotropic adhesive | High thermal conductivity | Low viscos gel | Prevent thermal propagation | Self-adhesive properties |

Download

You can find all the details about our silicone solutions in our detailed product brochure:

Download

You can find all the details about our silicone solutions in our detailed product brochure:

You may also be interested in

Industries

Our products are used in pioneering technologies in a wide range of industries.

Industries

Our products are used in pioneering technologies in a wide range of industries.