Polyurethane

systems for

electronics

Potting, bonding, sealing and thermal management with 2K polyurethane systems from Wevo

From potting compounds to adhesives, sealants and gap fillers – our reactive PU systems address key challenges in modern electronics. They offer long-term protection, enable targeted thermal management and support efficient high-volume production. On request, our polyurethane resins can be tailored precisely to your individual requirements. Explore our solutions – or get in touch with us today.

PU potting compounds | High-performance PUR adhesives | Polyurethane sealants | Polyurethane gap fillers | Soft-elastic polyurethane gels | PU coatings

Our polyurethane portfolio at a glance

Wevo-Chemie is an experienced polyurethane manufacturer and developer of innovative potting resins based in Germany. Our portfolio includes flame-retardant polyurethane potting compounds to thixotropic and heat-resistant sealants and thermally conductive gap fillers.

We can customise many technical properties – for example, optical requirements. Our materials are available as standard in natural colour and black. Additional colours such as grey or brown and translucent versions are also available – such as transparent polyurethane potting compounds for visible electronic components or optically clear resins for sensor-monitored applications.

Wevo products drive technological progress across many sectors – from automotive to power engineering and lighting technology.

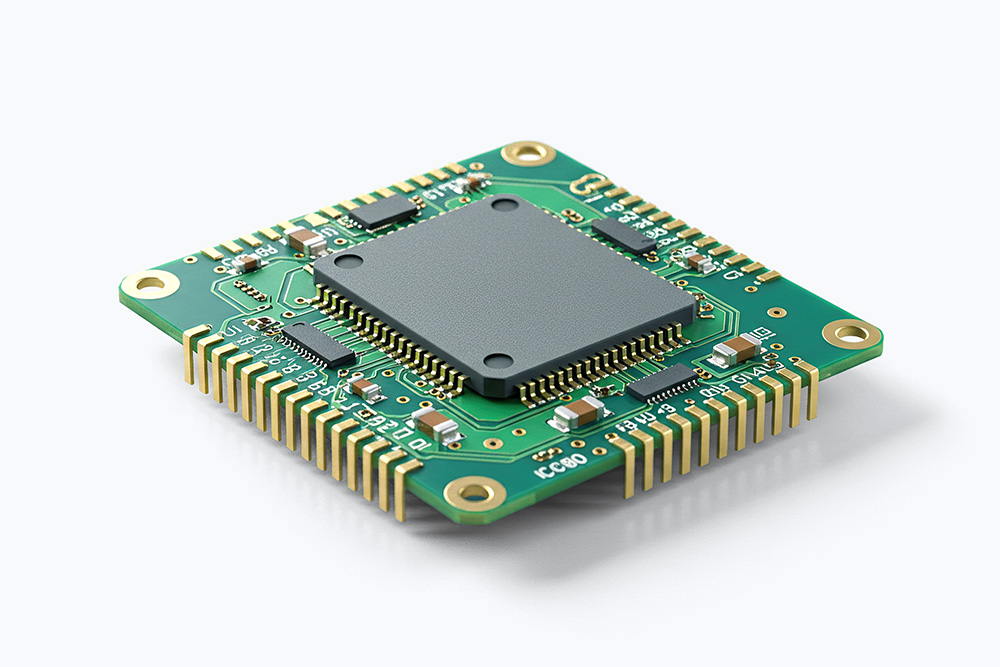

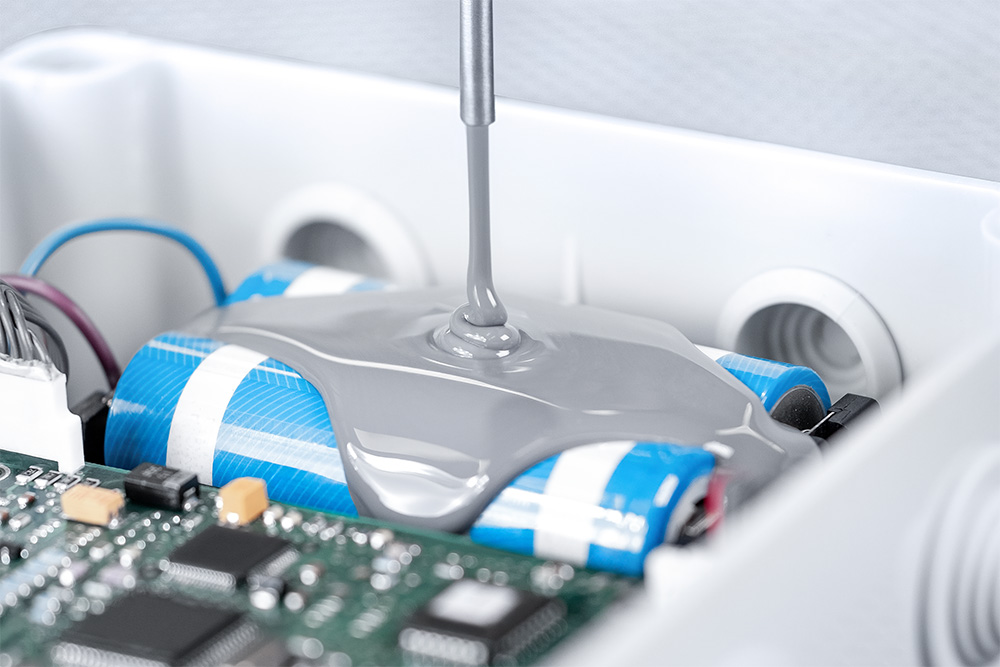

PU potting compounds for demanding electronics applications

Our polyurethane potting compounds provide reliable protection for components such as PCBs, sensors, energy storage systems, control units and electric motors. With excellent electrical insulation, outstanding flowability and strong adhesion – even to high-performance plastics – they form ideal 2K polyurethane potting compounds for modern components. On request, we can develop solutions precisely tailored to your requirements, such as thermally conductive or flame-retardant resins. Rely on our decades of expertise as a manufacturer of PUR potting compounds.

PU potting compounds for demanding electronics applications

Our polyurethane potting compounds provide reliable protection for components such as PCBs, sensors, energy storage systems, control units and electric motors. With excellent electrical insulation, outstanding flowability and strong adhesion – even to high-performance plastics – they form ideal 2K polyurethane potting compounds for modern components. On request, we can develop solutions precisely tailored to your requirements, such as thermally conductive or flame-retardant resins. Rely on our decades of expertise as a manufacturer of PUR potting compounds.

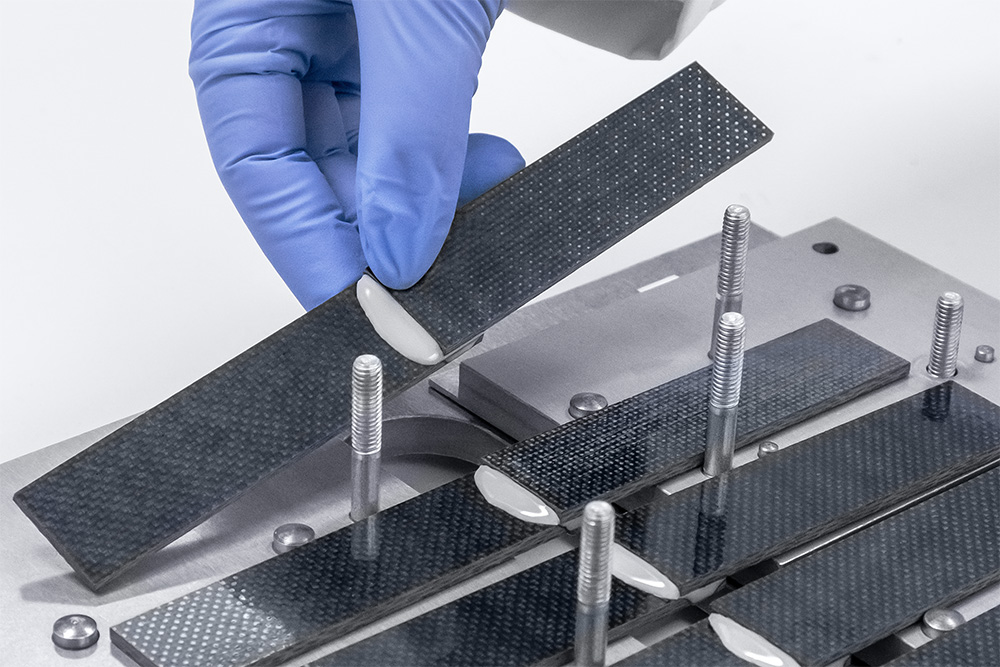

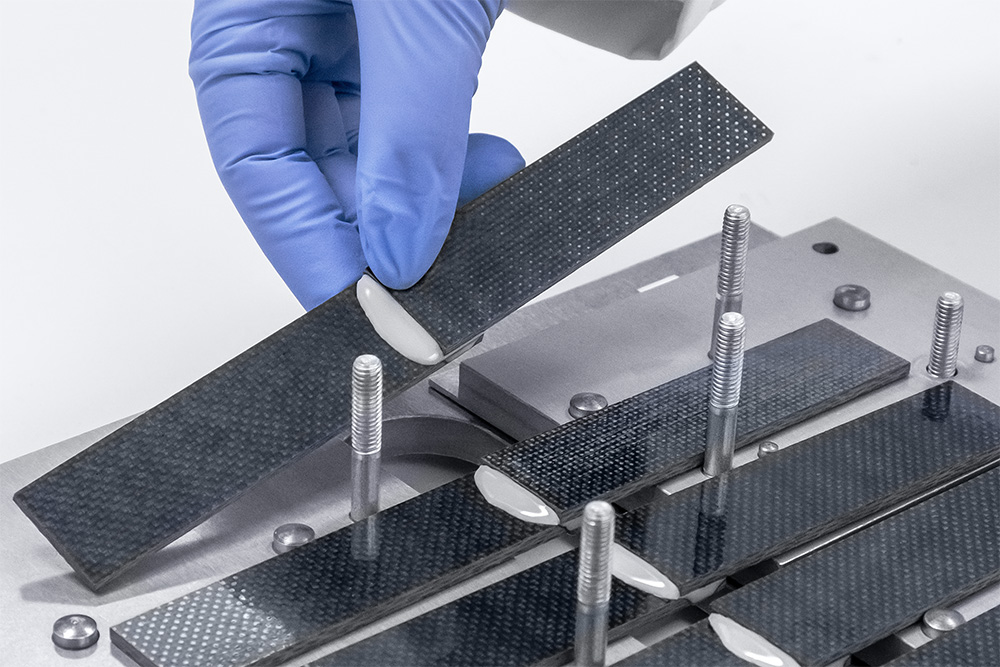

High-performance PUR adhesives for secure bonding

Wevo’s customisable PU adhesives ensure excellent adhesion to various substrates, including plastics, metals and ceramics – even without surface pre-treatment. Their reactivity and rheology can be flexibly adjusted from flowable to stable, making them ideal for demanding applications as electronic adhesives in power engineering and industrial environments. Our polyurethane adhesives also offer strong resistance to chemicals and temperature. We develop flame-retardant polyurethane adhesives to suit your customers’ requirements. And our specially developed thermally conductive 2K PU adhesives also enable structural bonding of components such as EV batteries.

High-performance PUR adhesives for secure bonding

Wevo’s customisable PU adhesives ensure excellent adhesion to various substrates, including plastics, metals and ceramics – even without surface pre-treatment. Their reactivity and rheology can be flexibly adjusted from flowable to stable, making them ideal for demanding applications as electronic adhesives in power engineering and industrial environments. Our polyurethane adhesives also offer strong resistance to chemicals and temperature. We develop flame-retardant polyurethane adhesives to suit your customers’ requirements. And our specially developed thermally conductive 2K PU adhesives also enable structural bonding of components such as EV batteries.

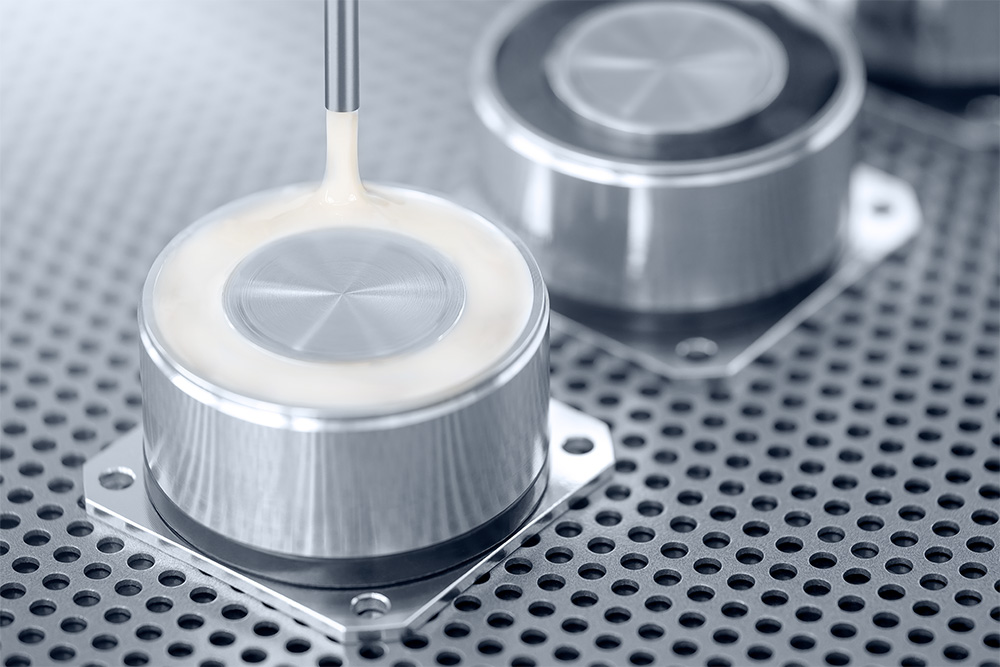

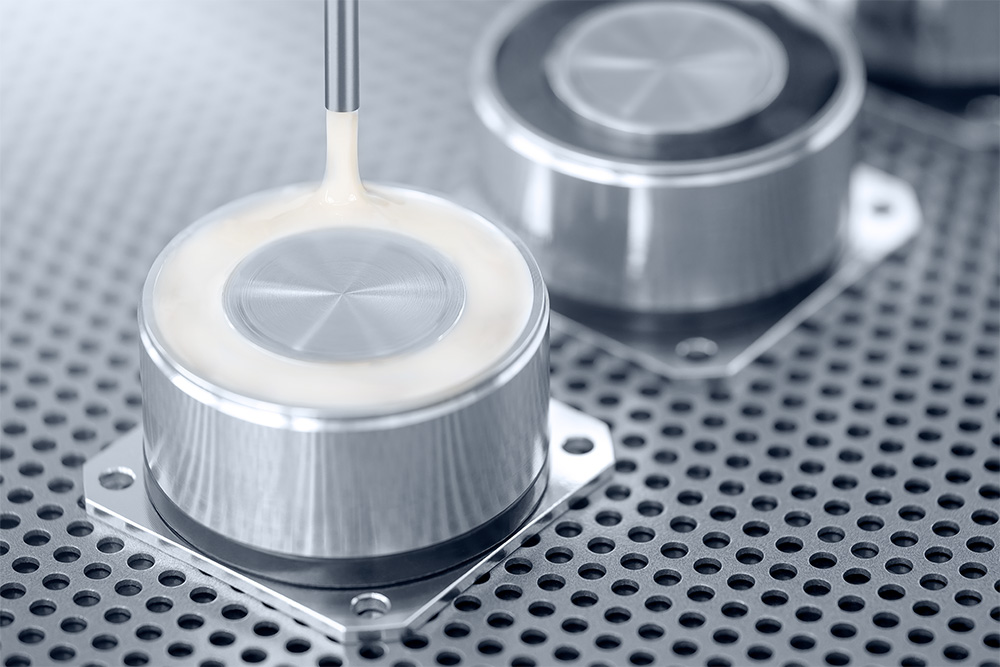

Polyurethane sealants for long-lasting, flexible sealing in industrial and electronic applications

Our PU sealants can be reliably applied as CIPG (cured-in-place gasket) or FIPG (formed-in-place gasket) systems. Rheology and reactivity can be adapted for automated production processes such as dispensing or screen printing – e.g. to create a thixotropic polyurethane sealant for complex geometries. Wevo’s electronic sealants are highly flexible with excellent elongation and recovery properties, ensuring effective sealing even under dynamic loads. Our portfolio also includes highly heat-resistant sealants and formulations with excellent media resistance and low water absorption.

Polyurethane sealants for long-lasting, flexible sealing in industrial and electronic applications

Our PU sealants can be reliably applied as CIPG (cured-in-place gasket) or FIPG (formed-in-place gasket) systems. Rheology and reactivity can be adapted for automated production processes such as dispensing or screen printing – e.g. to create a thixotropic polyurethane sealant for complex geometries. Wevo’s electronic sealants are highly flexible with excellent elongation and recovery properties, ensuring effective sealing even under dynamic loads. Our portfolio also includes highly heat-resistant sealants and formulations with excellent media resistance and low water absorption.

Wevo’s polyurethane systems are engineered to meet the demands of modern electronics – enabling technological advancement across various industries.

Wevo’s polyurethane systems are engineered to meet the demands of modern electronics – enabling technological advancement across various industries.

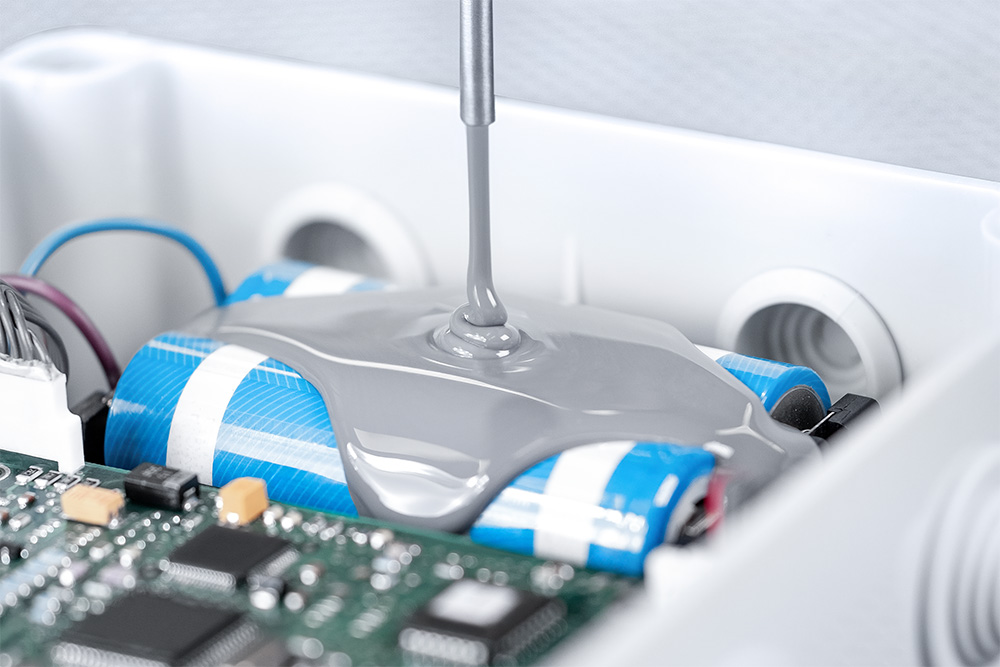

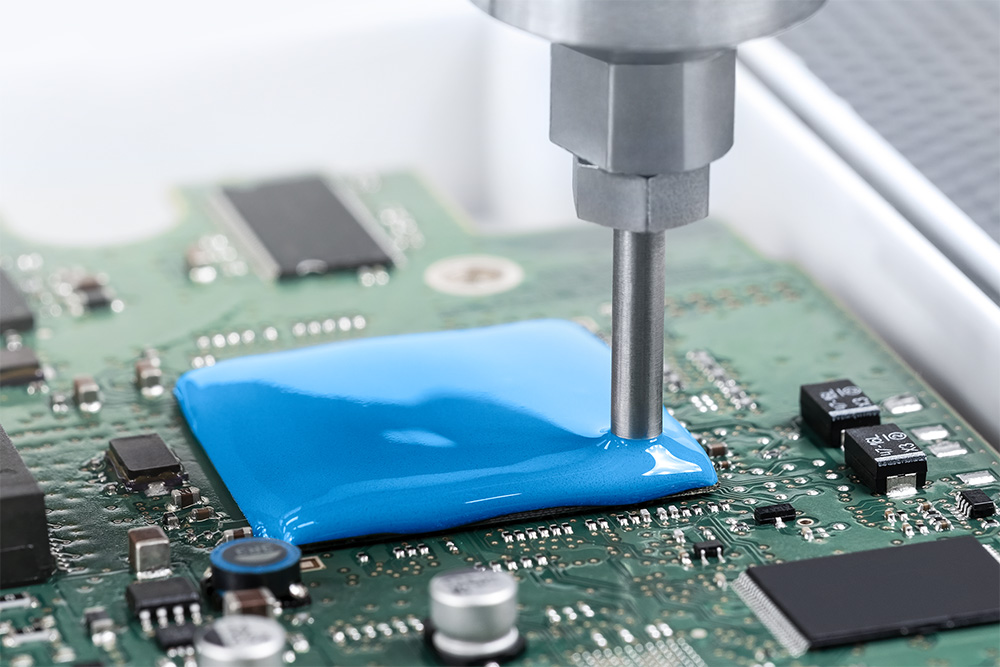

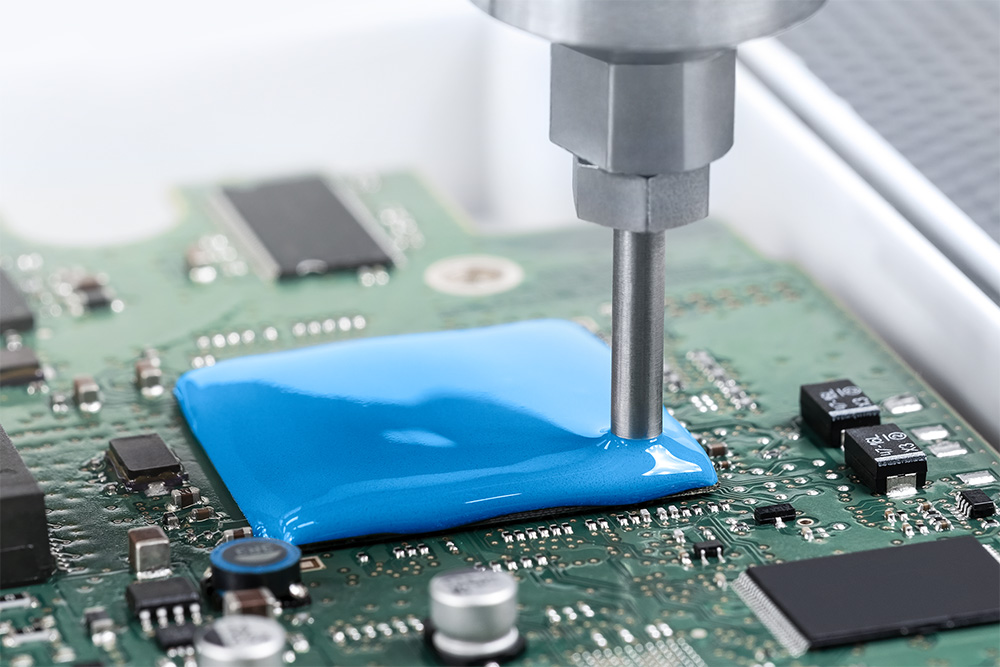

Polyurethane gap fillers for targeted thermal management

Wevo’s polyurethane gap fillers combine customisable flow properties with excellent thermal conductivity of up to 2.0 W/m·K. Our formulations can be precisely tailored to specific requirements in thermal management. Further customisations are also possible, such as flame-retardant polyurethane gap fillers. Thanks to their low sedimentation, the 2K materials remain reliable throughout processing, even during extended storage, and ensure uniform dispensing, making them ideal for the automated production of modern technologies. Typical applications include battery modules, power electronics, on-board chargers and sensors and control units for high-voltage systems.

Polyurethane gap fillers for targeted thermal management

Wevo’s polyurethane gap fillers combine customisable flow properties with excellent thermal conductivity of up to 2.0 W/m·K. Our formulations can be precisely tailored to specific requirements in thermal management. Further customisations are also possible, such as flame-retardant polyurethane gap fillers. Thanks to their low sedimentation, the 2K materials remain reliable throughout processing, even during extended storage, and ensure uniform dispensing, making them ideal for the automated production of modern technologies. Typical applications include battery modules, power electronics, on-board chargers and sensors and control units for high-voltage systems.

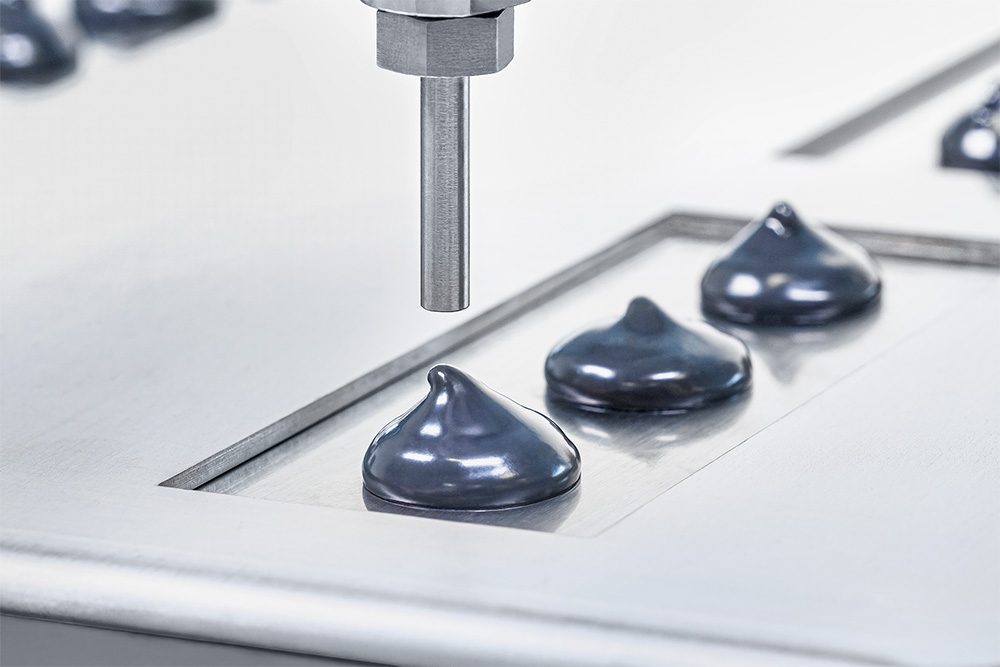

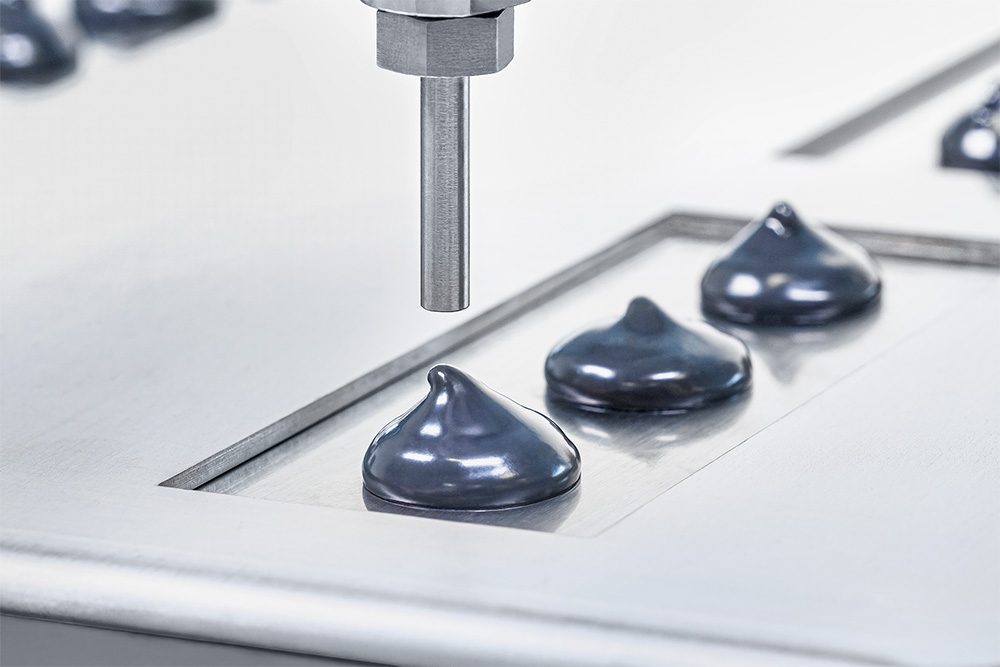

Soft-elastic polyurethane gels for sensitive electronic components

Reactive 2K PU gels offer excellent protection in applications such as batteries, control units and power electronics – for example by reliably damping mechanical vibrations and shocks. With strong adhesion to metals and plastics, they help extend component service life. Thixotropic, flame-retardant and thermally conductive polyurethane gels are available, along with versions featuring self-healing properties (reversion). WEVOPUR gels are also resistant to UV and ageing, making them suitable for outdoor use and transparent enclosures.

Soft-elastic polyurethane gels for sensitive electronic components

Reactive 2K PU gels offer excellent protection in applications such as batteries, control units and power electronics – for example by reliably damping mechanical vibrations and shocks. With strong adhesion to metals and plastics, they help extend component service life. Thixotropic, flame-retardant and thermally conductive polyurethane gels are available, along with versions featuring self-healing properties (reversion). WEVOPUR gels are also resistant to UV and ageing, making them suitable for outdoor use and transparent enclosures.

PU coatings with excellent chemical resistance and high electrical insulation

Our PU coatings achieve very low water absorption (<1%) combined with high dielectric strength (typically >20 kV/mm) – ideal for use in power engineering, the automotive industry and sensor technology. The careful adjustment of material properties ensures protection against moisture, chemicals and electrical influences. These solvent-free 2K PU systems offer excellent adhesion to metals, plastics and PCBs. They can also be formulated with customised hardness, viscosity and reactivity – as a thixotropic polyurethane coating for vertical or complex geometries, for example. Flame-retardant variants are also available on request.

PU coatings with excellent chemical resistance and high electrical insulation

Our PU coatings achieve very low water absorption (20 kV/mm) – ideal for use in power engineering, the automotive industry and sensor technology. The careful adjustment of material properties ensures protection against moisture, chemicals and electrical influences. These solvent-free 2K PU systems offer excellent adhesion to metals, plastics and PCBs. They can also be formulated with customised hardness, viscosity and reactivity – as a thixotropic polyurethane coating for vertical or complex geometries, for example. Flame-retardant variants are also available on request.

Interested? Contact us today!

Wevo-Chemie is your partner for polyurethane resins. Our experts are on hand to advise you and answer your questions.

Call us on +49 711 167 61-0 or send your enquiry via Email.

Interested? Contact us today!

Wevo-Chemie is your partner for polyurethane resins. Our experts are on hand to advise you and answer your questions.

Call us on +49 711 167 61-0 or send your enquiry via Email.

Applications for our customised polyurethane systems

PU resins from Wevo are used in a wide range of components – applications range from battery modules, power electronics and sensors to on-board chargers and electric motors.

Performance and design flexibility for supercapacitors

WEVOPUR 512 FL polyurethane potting compound fixes cells securely inside the housing, enabling customised adaptations in component design. In addition, the thermally conductive formulation supports heat management – boosting electrical performance and service life.

Performance and design flexibility for supercapacitors

WEVOPUR 512 FL polyurethane potting compound fixes cells securely inside the housing, enabling customised adaptations in component design. In addition, the thermally conductive formulation supports heat management – boosting electrical performance and service life.

Thermally conductive potting for solar inverters

To ensure safe and reliable power conversion, specially developed PUR potting compounds dissipate heat effectively – also in microinverters. These products offer high thermal conductivity and flame-retardant properties in accordance with UL 94 V-0.

Thermally conductive potting for solar inverters

To ensure safe and reliable power conversion, specially developed PUR potting compounds dissipate heat effectively – also in microinverters. These products offer high thermal conductivity and flame-retardant properties in accordance with UL 94 V-0.

Reliable PCB protection with polyurethane potting

WEVOPUR 512 FLE offers significantly better corrosion resistance compared to traditional conformal coatings. They are therefore ideal for sensitive electronics in battery management systems, power electronics and control units, even in harsh environments.

Find out more

Reliable PCB protection with polyurethane potting

WEVOPUR 512 FLE offers significantly better corrosion resistance compared to traditional conformal coatings. They are therefore ideal for sensitive electronics in battery management systems, power electronics and control units, even in harsh environments.

Find out more

Polyurethane potting compound for sensor and antenna applications

From flush exterior door handles to keyless systems – tailor-made PU potting resins for the automotive industry provide long-term protection for electronic components in modern vehicle access systems and ensure reliable radio wave transmission. Adaptable flow behaviour and pot life enable efficient manufacturing processes.

Find out more

Polyurethane potting compound for sensor and antenna applications

From flush exterior door handles to keyless systems – tailor-made PU potting resins for the automotive industry provide long-term protection for electronic components in modern vehicle access systems and ensure reliable radio wave transmission. Adaptable flow behaviour and pot life enable efficient manufacturing processes.

Find out more

Why polyurethane? Properties and benefits for your technical components

Polyurethanes are reactive polymers that can be precisely formulated to suit a wide range of industries and requirements. This enables the development of materials such as flame-retardant PU resins, thixotropic elastomers and electrically insulating coatings. Two-component systems consist of resin and hardener, reacting in a defined mixing ratio. They can be dosed with precision and are ideal for automated series production. Here is an overview of the advantages of our tailor-made polyurethane systems:

- Customisable flow behaviour and reactivity: adaptable to different manufacturing processes and component designs

- Wide operating temperature range (e.g. –40 °C to +130 °C or +165 °C): thermal stability at continuous service temperatures of up to 165 °C extends the operating range of certain systems, even in demanding environments

- Excellent electrical insulation properties: suitable for low to high-voltage applications

- Thermally conductive versions available: for active thermal management in batteries, LED modules or power electronics

- UL 94-compliant flame-retardant systems available: compliance with safety standards, e.g. in automotive or industrial applications

- Reliable adhesion: durable bonding and individual protection against harsh environmental influences for electronic components

Many Wevo materials can be processed at room temperature – with no external heating required. This allows for energy-efficient and seamless integration into existing production processes. Also, special formulations enable shorter cycle times or specific curing requirements. These PU resins can be activated at elevated temperatures or thermally accelerated for curing.

Why polyurethane? Properties and benefits for your technical components

Polyurethanes are reactive polymers that can be precisely formulated to suit a wide range of industries and requirements. This enables the development of materials such as flame-retardant PU resins, thixotropic elastomers and electrically insulating coatings. Two-component systems consist of resin and hardener, reacting in a defined mixing ratio. They can be dosed with precision and are ideal for automated series production. Here is an overview of the advantages of our tailor-made polyurethane systems:

Customisable flow behaviour and reactivity: adaptable to different manufacturing processes and component designs

Wide operating temperature range (e.g. –40 °C to +130 °C or +165 °C): thermal stability at continuous service temperatures of up to 165 °C extends the operating range of certain systems, even in demanding environments

Excellent electrical insulation properties: suitable for low to high-voltage applications

Thermally conductive versions available: for active thermal management in batteries, LED modules or power electronics

UL 94-compliant flame-retardant systems available: compliance with safety standards, e.g. in automotive or industrial applications

Reliable adhesion: durable bonding and individual protection against harsh environmental influences for electronic component

Many Wevo materials can be processed at room temperature – with no external heating required. This allows for energy-efficient and seamless integration into existing production processes. Also, special formulations enable shorter cycle times or specific curing requirements. These PU resins can be activated at elevated temperatures or thermally accelerated for curing.

Representative polyurethane products – technical information at a glance

Wevo is committed to uncompromising quality. Our PU systems comply with strict regulations and standards for chemical materials and their safe use, including certifications such as UL 94 and EN 45545-2.

| Product category | Polyurethane potting compound | Polyurethane adhesive | Polyurethane sealant | Polyurethane gap filler | Polyurethane gel | Polyurethane coating |

| WEVOPUR | 512 FLE | 58093 | 78901 | 56005 FL | 413 | 60200 FL T |

| WEVONAT | 900 E | 600 | 385 | 900 | 623 | 900 E |

| Operating temperature [°C] | –40 up to +130 | –40 up to +130 | –60 up to +120 | –40 up to +130 | –40 up to +120 | –40 up to +130 |

| Flammability UL 94 | V-0 | – | – | V-0 | – | V-0 |

| Shore hardness A/D | 80–85 / 30–40 | -- / 60–70 | 50–60 / -- | -- / 45–55 | gel | -- / 38–48 |

| Thermal conductivity [W/m·K] | 0.80 | 0.37 | 0.30 | 1.50 | 0.20 | 0.80 |

| Mixed viscosity [mPa·s] | 900–1,400 | 1,600–2,200 | 4,000–8,000 | 6,000–10,000 | 8,000–12,000 | 3,000–4,500 |

| Feature | Encapsulant approved in accordance with EN 45545-2 (railway applications) | General adhesive with high chemical resistance | Highly reactive thixotropic sealant | Flowable gap filler | Plasticiser-free gel | Suitable for dam-and-fill processes |

Downloads

Further technical details about our polyurethane electro-casting resins can be found in our product brochures:

Download

Further technical details about our polyurethane electro-casting resins can be found in our product brochures:

You may also be interested in

Industries

Our products are used in pioneering technologies in a wide range of industries.

Industries

Our products are used in pioneering technologies in a wide range of industries.