Electrochemical corrosion can significantly reduce an electronic component’s service life and reliability. This effect is greatly enhanced by moisture or contamination from production residues such as fluxes. The materials traditionally employed to coat printed circuit boards (PCBs) quickly reach their limits here – and in harsh environments their protective effect is no longer sufficient. A proven Wevo potting compound for electronic components provides a high-performance alternative here.

STUDY FRAMEWORK

WEVOPUR 512 FLE is a proven two-component electro potting resin that was formulated from the development stage onward with the aim of minimising corrosion risks, amongst other things. Classic flame retardants such as phosphate compounds were avoided, for instance. Owing to these special properties, the PU potting compound is suitable not only for capacitors or fieldbus distributors but also for applications involving printed circuit boards.

The effectiveness of WEVOPUR 512 FLE for protecting PCBs against electrical corrosion has been investigated and confirmed in a study conducted by DTU under the umbrella of the CreCon industrial consortium (Consortium for Climatically Reliable Electronics).

EXPERIMENTAL SETUP AND METHODOLOGY

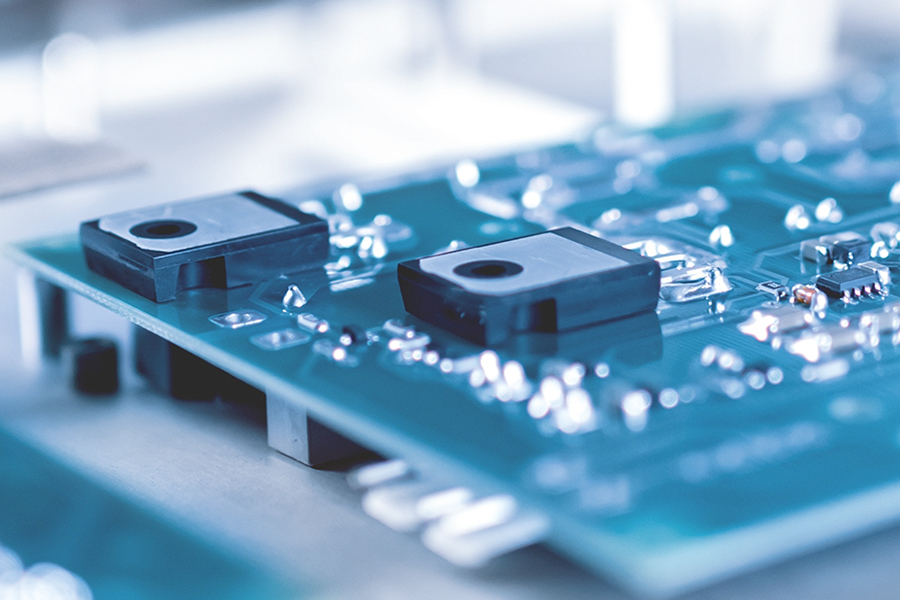

SIR (Surface Impedance Resistance) boards with comb-shaped conductors were used as test specimens. They were either pre-cleaned or deliberately contaminated and then coated. For this purpose, the research team used a conventional conformal coating or WEVOPUR 512 FLE.

In the following, the SIR boards were subjected to a series of practical stress tests to evaluate the materials’ protective effect. This was done by measuring the electrical impedance – any changes to the surface, for example due to corrosion, impact on these values.

RESULTS: INFLUENCE OF CONTAMINATION

Contamination is commonplace in PCB manufacturing, for instance owing to flux residues or fingerprints brought about by improper handling (NaCl). For this reason, the scientists began by investigating the influence of contamination on the development of electrical corrosion. This entailed subjecting the coated SIR boards to a predefined cyclic climatic stress test at a constant relative humidity – alternately for 2 hours at 40 °C and then for a further 2 hours at 65 °C over 20 consecutive cycles. The change from 65 to 40 °C accelerates the condensation of water vapour, which can favour the development of corrosion processes when voltage is applied.

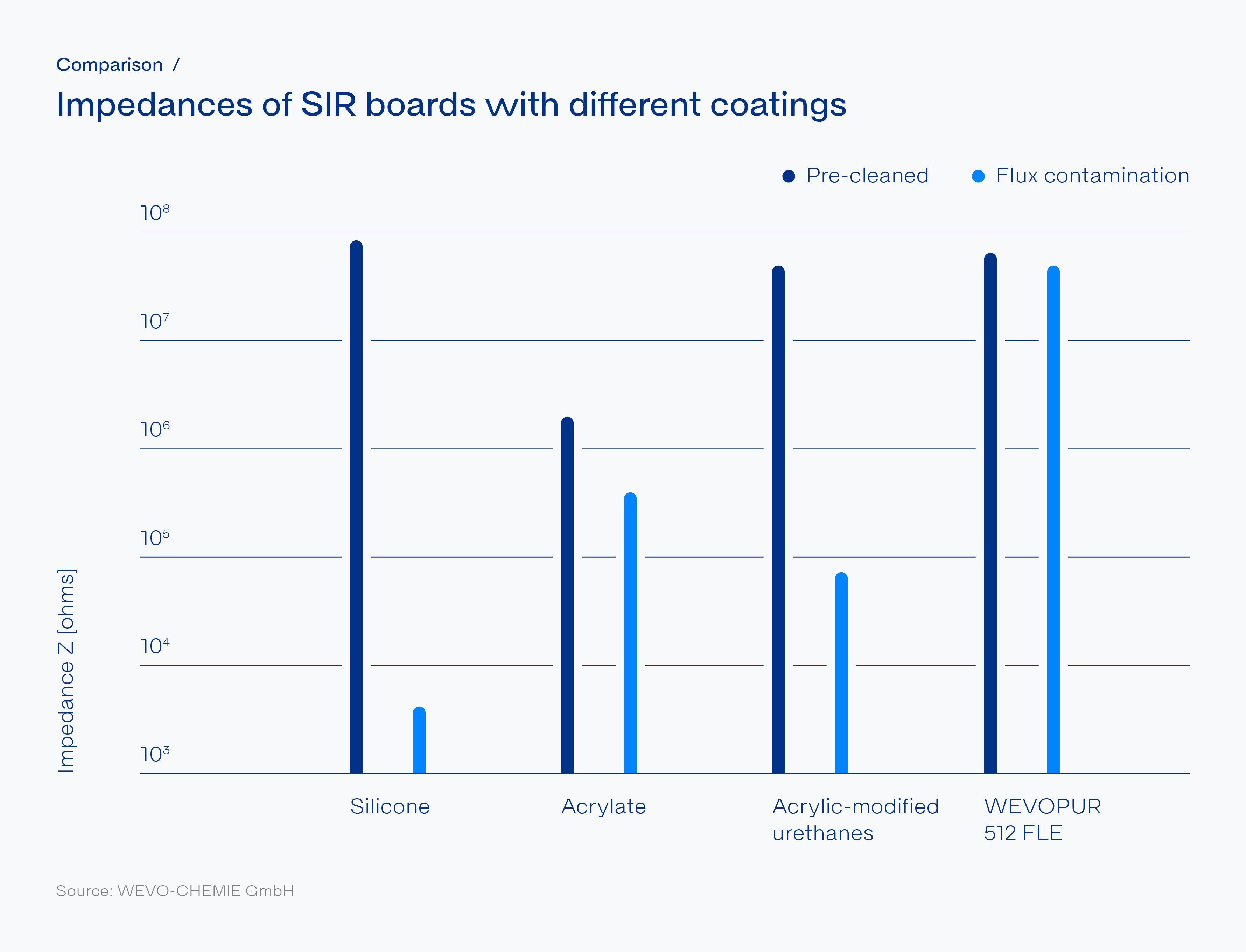

With the pre-cleaned PCBs, a significant drop in impedance was only observed with one of the conformal coatings (from approximately 108 ohms to around 2⋅106 ohms). The situation was different when it came to the test specimens contaminated with flux: only the Wevo potting compound – with 6.5⋅107 ohms on the contaminated PCB – performed practically as well as on a clean PCB (5⋅107 ohms); the conformal coatings showed significantly worse performance here. The results are shown in the diagram below:

More tests were carried out to investigate the resistance of Wevo’s electro potting resin when immersed in water and determine the influence of a special-purpose hardener with optimised adhesion. Both trials further underlined the Wevo potting compound’s suitability for PCBs.

CONCLUSION

“The test results confirm that our electro potting resin provides effective protection against electrical corrosion”, explains Romain Kraft, Team Leader PU Development at Wevo. What’s more, the potting compound offers flame-retardant properties in accordance with UL 94 V 0 and is admissible even in critical environments such as passenger trains. EN 45545 2, the European railway standard, sets out strict rules here regarding fire behaviour and smoke development, which are fulfilled by the material as well. Kraft: “That’s why WEVOPUR 512 FLE has decisive advantages over conventional conformal coatings in demanding applications – and modern electronic components benefit from higher operational reliability, longer maintenance cycles and lower failure rates”.

A detailed report of the test results can be found under the following link:

www.wevo-chemie.com/scio/pcb